Three dimension struction ,fiber with high elastic with excllent touch.

Three dimension struction ,fiber with high elastic with excllent touch.

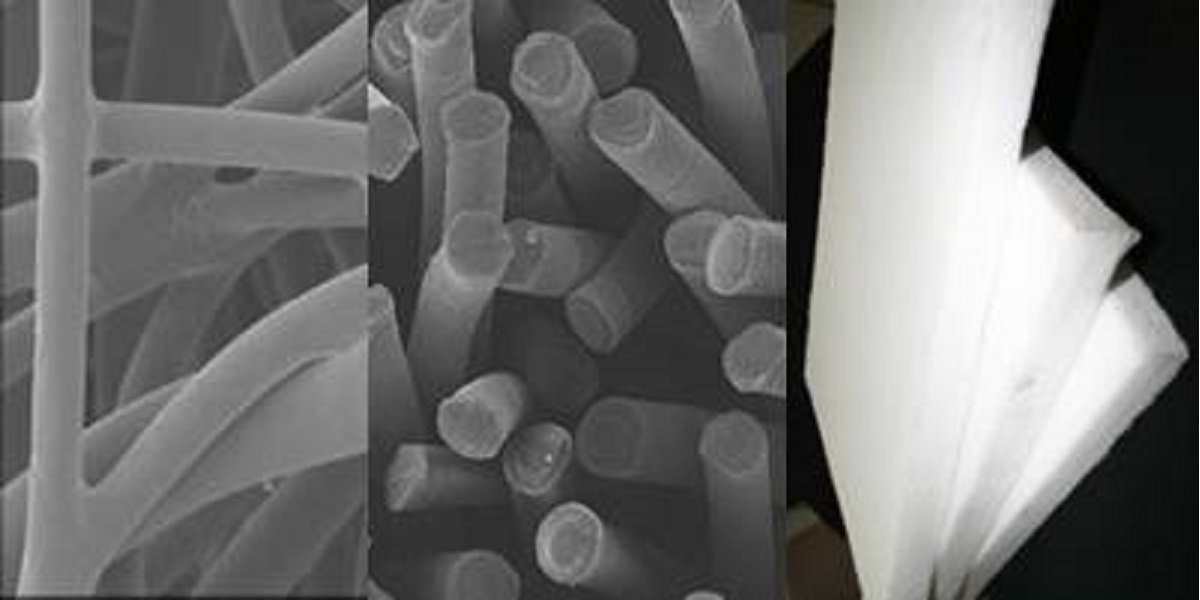

Through the two-component composite spinning technology, the fibers obtained by spinning two kinds of fibers with different melting points in the form of sheath-core structure are environmentally friendly and can replace glue for bonding.

Using unique spinning technology, the fibers can be processed into ultra-fine fibers after finishing treatment, which can be processed into shoe materials, artificial leather and industrial wipes.

Microfine denier, with super feather touch, it can be widely used in the filling instead of duck down feather.

The melted PP is spun, drawn, crimped, heat-set and cut to obtain polypropylene staple fiber.

PPS fiber can be worked at the high temperature(190d.c) in long time. widely be used for the filter and fireproof garments etc.

It is made of polymers including eco-friendly materials(Polyester or Polypropylene),and it has excelletn dispersibility and efficiency in wet-laid process.be application for papermaking,filter,building construction , cement sheets, tiles and pipes etc